ClearStream Solid Contact Clarifiers

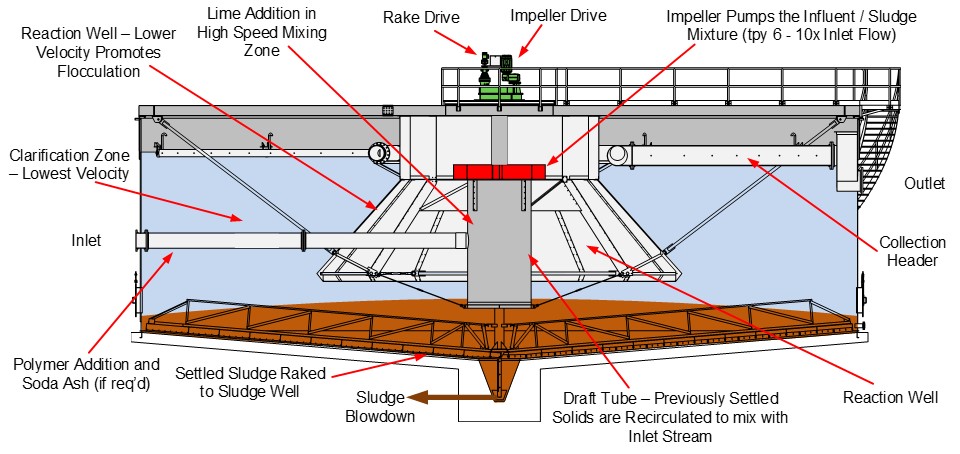

ClearStream Solids Contact Clarifiers integrate rapid mixing, flocculation, and sedimentation within a single tank to deliver high-rate clarification in a compact footprint. Process mixing and solids recirculation are achieved using a radial or axial flow impeller, ensuring continuous contact between influent water and recycled solids.

Flocculation occurs within the reaction well, where influent is blended with concentrated settled solids to promote particle collisions and accelerated floc growth.

Sedimentation takes place in the surrounding clarification zone, where enlarged floc particles settle efficiently under controlled hydraulic conditions.

The clarifier is comprised of four primary zones:

-

Mixing zone

-

Flocculation (reaction) zone

-

Sludge blanket zone

-

Clarification zone

An impeller continuously withdraws dense settled solids from the bottom of the unit, combines them with the lower-solids influent, and redistributes the mixture into the reaction well. This internal solids recirculation enhances floc formation, improves settling characteristics, and increases overall treatment efficiency.

Solids Contact Clarifier Applications

Solids Contact Clarifiers (SCCs) are high-rate clarification systems used in municipal and industrial water and wastewater treatment to efficiently remove color, turbidity, hardness, and suspended solids. By combining rapid mixing, flocculation, and clarification in a single unit, SCCs deliver consistent performance while minimizing footprint and chemical usage.

These systems are widely applied in water treatment plants for softening and clarification, as well as in wastewater treatment plants as polishing or tertiary clarifiers.

- Surface water clarification

- Cold lime softening and lime–soda ash softening

- Pretreatment for membrane systems (RO, NF, UF)

- Pretreatment to conventional filtration

- Acid mine drainage treatment

- Tertiary wastewater treatment and phosphorus removal

- Heavy metals removal

Advantages in Lime Softening Applications

Solids Contact Clarifiers are especially effective for lime softening of groundwater. The recirculation of precipitated solids enhances contact between particles, promoting crystal growth and floc formation. This results in:

- Larger, denser precipitate

- Improved settling rates

- Higher solids loading capacity

- Thicker, more concentrated waste sludge

The improved solids contact mechanism leads to better hardness removal and more stable clarifier operation compared to conventional clarification processes.

Industrial and Advanced Treatment Applications

Beyond municipal treatment, Solids Contact Clarifiers are proven in industrial water and wastewater treatment, including chemical precipitation processes for metals removal and cooling tower make-up water treatment, where consistent effluent quality is critical.

Integrated Process Design

Combines rapid mixing, flocculation, and clarification in a single tank, reducing footprint and simplifying system layout.

High-Efficiency Solids Recirculation

Radial or axial impeller continuously recirculates settled solids at 6–10× influent flow, increasing particle contact, accelerating floc growth, and improving settling performance.

Low Shear, Low Head Impeller

High-flow impeller provides effective mixing while minimizing floc breakup and reducing power requirements.

Dedicated Reaction Well

Controlled low-velocity zone promotes stable flocculation following high-speed mixing and chemical addition.

Defined Hydraulic Zones

Engineered mixing, reaction, sludge blanket, and clarification zones optimize solids separation and effluent quality under varying load conditions.

Enhanced Sludge Thickening

Continuous solids recycling produces larger, denser floc and a thicker waste sludge, improving downstream dewatering efficiency.

Mechanical Sludge Collection

Settled solids are raked to a central sludge well for controlled blowdown and ongoing solids contact.

Chemical Feed Integration

Designed for lime, polymer, and soda ash addition within appropriate mixing zones to support softening, metals removal, and advanced treatment processes.

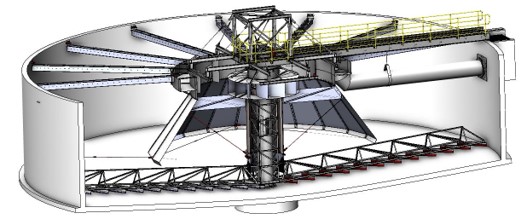

3D Models of Every Project

ClearStream develops a detailed 3D model for every unit manufactured, ensuring accurate fit-up and seamless integration with site-specific layouts. These models also serve as a valuable tool for operator training and system familiarization, providing clear insight into unit design and operation.

Clients are provided access to the 3D models, allowing them to view and manipulate the equipment from their own office or facility. This capability enables operations and maintenance personnel to virtually inspect the unit, plan maintenance activities, and understand internal components—without draining the tank or interrupting operation.

Continue to explore

Let’s Solve Your Process Treatment Challenge

+1 801 676 1890

info@clearstreameng.com

Speak with a ClearStream engineer about your process needs. We’ll help you identify the best solution for your system and application.