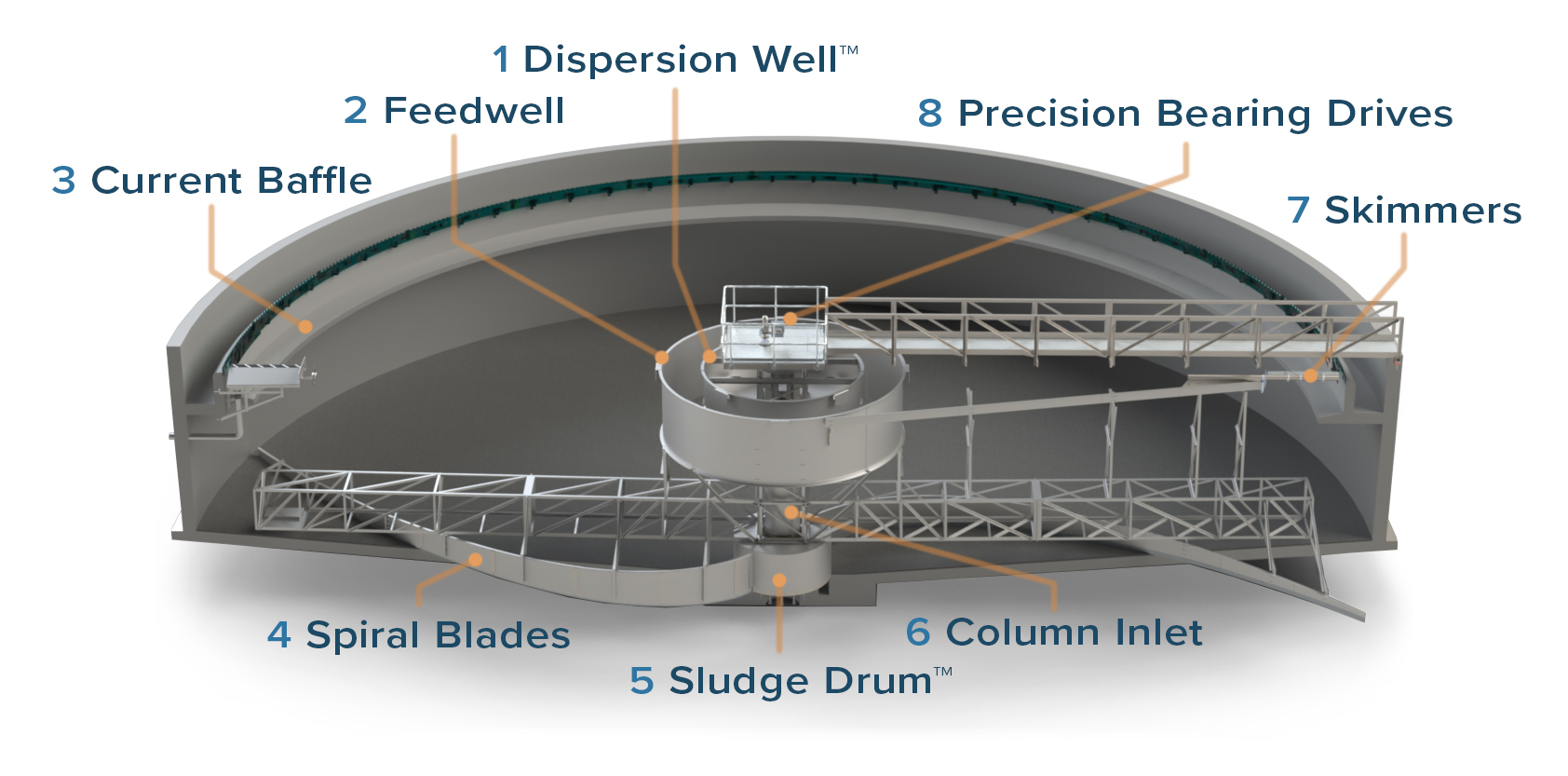

ClearStream Nautilus™ Spiral Blade Clarifiers

Just like its namesake, the spiral blades of the ClearStream Nautilus™ Spiral Blade Clarifiers are designed for function and strength and the precise sludge transportation rate required by the application and the clarifier sizing.

Because of the high rate of sludge removal with spiral blades, there is practically no risk of denitrification or secondary phosphorus release due to sludge age. In addition, if the Rakes are run at the proper speed, there is little or no plume formation which could impact the effluent solids level.

Spiral Blade Clarifiers

Standard Options

1. Dispersion Well™ (IDW) The unique IDW design has demonstrated, in side-by-side testing, substantial improvements in lowered TSS over other EDI designs.

2. Feedwell: Allows the solids a low energy area in which they may form larger flocs.

3. Current Baffle: The primary function is to eliminate wall currents and prevents clarifier short circuiting.

4. Blades: Segmented Blades, Half Radius Additional Blades are options

5. Sludge Drum™ The Sludge Drum rotates with the blades and therefore is always exposed to the highest concentration of sludge.

6.Column Inlet: This feed configuration maximizes the effectiveness of the IDW.

7.Skimmers: Standard Skimmers, Full Radis

Skimmers, and Ducking Skimmers are all available.

8.Precision Bearing Drives: A proven design which does not require a lower bearing; maximizes drive life and minimizes drive maintenance

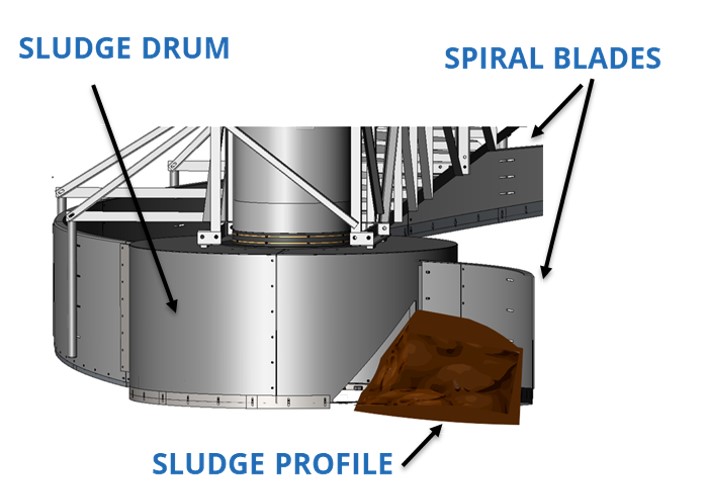

Sludge Drum™ Option

The Sludge Drum™ rotates with the blades and therefore it is always exposed to the highest concentration of sludge. In addition, the opening matches sludge profile, further reducing the amount short circuiting.

Using this design, ClearStream can convert a Suction Pipe Header to a Spial Blade Rake without compromising the concrete floor of the unit.

Nautilus™ Spiral Blade Clarifier Applications

ClearStream Nautilus™ Spiral Blade Clarifiers are designed for rapid and reliable sludge collection in municipal and industrial clarification applications where consistent solids removal and low maintenance operation are critical.

-

Primary and secondary wastewater clarification

-

Tertiary clarification and polishing

-

Biological nutrient removal (BNR) systems

-

Phosphorus removal and chemical precipitation

-

Municipal water treatment clarification

-

Industrial process water and wastewater treatment

-

Clarifier retrofits and upgrades (including suction header conversions)

Minimal Risk of Denitrification or Secondary Phosphorus Release

High sludge removal rate minimizes sludge age within the clarifier.

Low Effluent TSS and Reduced Plume Formation

Proper rake speed results in little to no plume formation that could impact effluent quality.

Nothing to Plug Underwater

No suction orifices, seals, or horizontal suction piping that can clog.

Lower Maintenance than Suction Systems

Eliminates debris accumulation issues common in suction headers and pipes.

Consistent Sludge Transport Regardless of Solids Loading

Positive mechanical conveyance to sludge pit or rotating manifold.

Faster Sludge Removal vs. Segmented Blades

Many engineers consider spiral blade clarifiers to be rapid solids removal clarifiers.

Spiral Blade Sludge Collection System

Logarithmic spiral blades with a constant 30–35° attack angle and increasing depth toward the center provide continuous, positive sludge transport.

Rapid Solids Transport

Settled sludge is collected continuously along the blade and conveyed to the center in one or two passes of the rake arm.

Influent Dispersion Well (IDW)

Proven design that reduces TSS and improves hydraulic distribution compared to conventional EDI feedwells.

Flocculating Feedwell

Low-energy zone that promotes formation of larger, denser floc particles.

Precision Bearing Drive

Upper bearing design with no lower submerged bearing, maximizing drive life and minimizing maintenance.

Optional Sludge Drum

Rotates with the spiral blades and continuously receives the highest concentration of sludge, reducing short-circuiting.

Density Current Baffle

Eliminates wall currents and prevents clarifier short-circuiting.

Configurable Designs

Multiple spiral blades for large diameters, dual-slope bottoms, additional radius arms, and multiple skimmer options available.

Engineered for rapid solids removal.

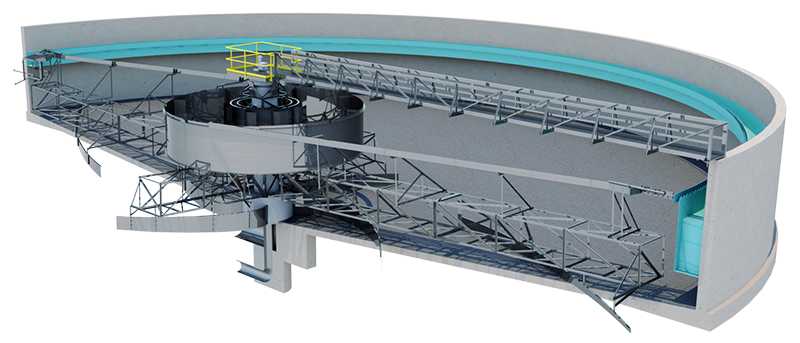

3D Models of Every Project

ClearStream develops a detailed 3D model for every unit manufactured, ensuring accurate fit-up and seamless integration with site-specific layouts. These models also serve as a valuable tool for operator training and system familiarization, providing clear insight into unit design and operation.

Clients are provided access to the 3D models, allowing them to view and manipulate the equipment from their own office or facility. This capability enables operations and maintenance personnel to virtually inspect the unit, plan maintenance activities, and understand internal components—without draining the tank or interrupting operation.

Continue to explore

Resources

Let’s Solve Your Process Treatment Challenge

+1 801 676 1890

info@clearstreameng.com

Speak with a ClearStream engineer about your process needs. We’ll help you identify the best solution for your system and application.