About Thickeners

Thickeners are used in municipal, industrial and minerals applications to take solids from other liquid solids separation processes and thicken the solids prior to further dewatering. The drive is mounted on the walkway or bridge. The rotating portion of the drive turns a structural torque tube or shaft, which in turn rotates the solids removal mechanism.

ClearStream cage driven and center column supported thickeners can be supplied in sizes in excess of 400’ diameter.

Thickener Options

- Pickets

- Blades on Posts

- Low Profile Rakes

- Auto-dilution Feedwell / Energy Dissipating Inlets

- Center column or shaft driven mechanisms

- High Torque, Heavy Duty Drives with Lifts

Thickener Types

- Municipal Thickeners

- Industrial Thickeners

- Hi Rate Thickeners

- Tailings Thickeners

- Paste Thickeners

Rakes with Pickets

As the pickets pass through the solids, they create channels which allow the water to escape. This release of water produces a higher percent solids. This design works best and heavier solids which tend to trap the water within the solids layer.

Blades on Posts

Blades on posts are another option to deal with heavy solids. This design in effect raises the rake structure out of the solids layer. The result is that the rake structure is not dragged through the solids layer. This in turn reduces the torque required to rake the solids to the center sump. This design is employed and applications that have a heavy solids layer.

Low Profile Rakes

Low profile rakes are another option to reduce the torque required for thickening solids. Rather than the traditional rake cage design, the rake arm is constructed either out of heavy-duty channel or a specially constructed box beam. In either design, the surface area of the rake mechanism is greatly reduced thus producing and equivalent reduction in the torque required to turn the rakes through the solids layer.

Auto-dilution Feedwell

An auto-dilution feedwell is used in mineral application to enhance the mixing and use of polymer dosing and reduce short-circuiting of the feed coming into the feedwell, which in turn, provides a more efficient and uniform settling of the solids.

Heavy Duty Drive Units

ClearStream can design Shaft or Cage Drives with lifts to accommodate any applications with high or heavy solids loads.

These drives use the robust primary and secondary reducers and precision main gear/bearings. They also include torque measurement display with an easy-to-read torque dial.

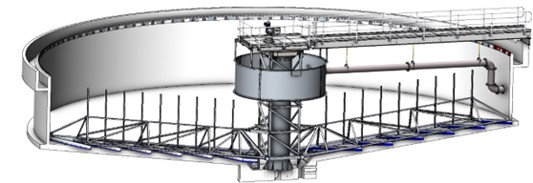

3D Models of Every Project

ClearStream produces a 3D model of every unit which we manufacture. These models are extremely valuable to ensure proper fit up. In addition, these models can be a useful tool for operators training and understanding of the unit design and operation. ClearStream provides these 3D models as well as the means for clients to view and manipulate these models at their own site or offices. This affords operations and maintenance personnel with a unique opportunity to “inspect” the unit prior to any planned maintenance without having to drain the tank.

Have A Process Problem? Need A Solution?

Our engineers will ensure you get the support needed to solve your process problems.